Today is Tuesday 14th September, I got back from walking the dogs this morning to find a note poked in the back door.

It was from ParcelForce telling me they’d tried to deliver a package while I was out and that I could pick it up from the local post office “after 1.00 pm”.

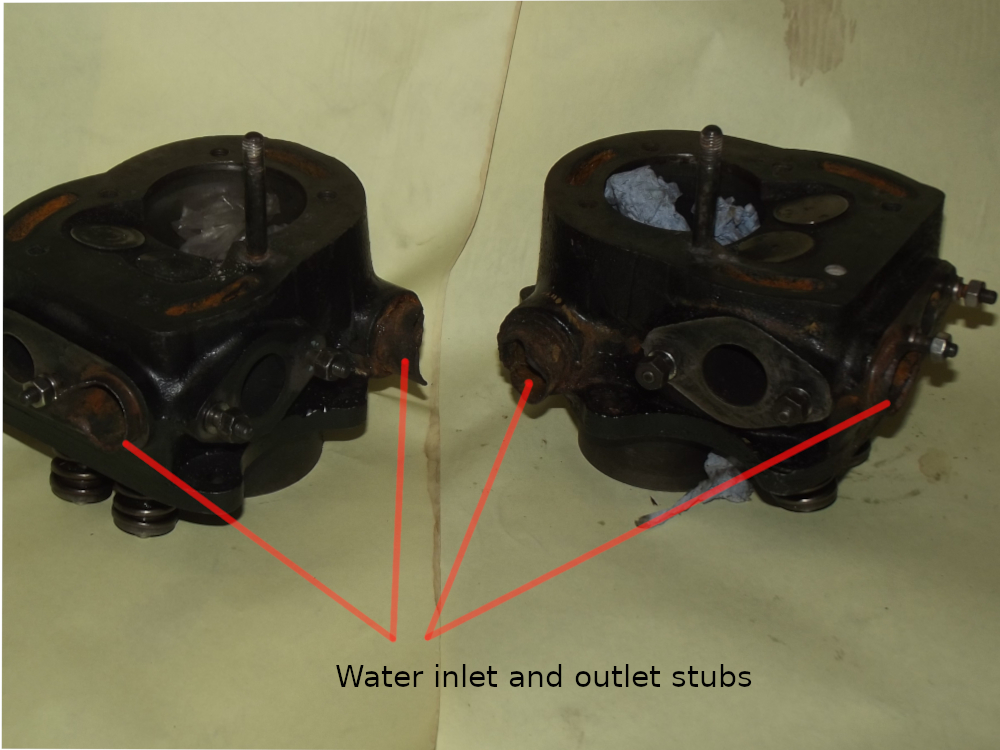

I went and picked it up and sure enough it was the LE cylinder barrels back, they’d been received at 3.01pm on Thursday according to the ParcelForce tracker and here they were back on the Tuesday morning, now that’s service!. It also shows how having the correct tooling to do a job can make it quick and easy.

Unfortunately I’ve not yet heard back from the LE Velo Club about my membership and until I have a member number I cannot use their Spares Scheme, I’ve a shopping list here ready to go as soon as I have that number!, mainly gaskets but I need those to re-assemble the engine.

In the meantime I’ve been having a look at making a fixing strap for the battery. The pukka strap is a piece of bent steel strip. I’d measured up and got as far as making the proverbial cardboard template when I had second thoughts, “Why not pinch the idea from BMW and secure the battery in place with a rubber strap?”.

I can remember that on my old R50 BMW there was a rubber strap over the top of the battery to secure it and I’d never had any problems with it so let’s have a look and see what’s needed.

I’ll need two frame anchor points, well there are the two points where the maker’s strap was fixed so it just means making up a pair of anchor hooks for the strap, not difficult, so what about the strap?.

The strap can be made from bands cut from an old inner tube, if I put them through a length of electrical braided sheathing that will give a more “professional” look to the job and anyway since it is under the saddle, while it can be seen it’s not out on open display as it were.

Details? A double hook is needed on the bike, one on either side of the battery. The ends of the rubber strap are looped over a short length of 4mm rod so the hooks go over the rod, on either side of the strap. I’ll need to glue the strap to get the correct length but I can either use “Super glue” or the glue from a puncture outfit for that.

When I took the barrels off I found that it would have been easier if I had had some “LE specific” tools, a 10mm plug spanner, a 2 BA box spanner and a 2 BA open ender, and a “special” for the cylinder base nuts.

While the special will have to come from the LE club I’ve been “on web” and sourced the others, while I don’t have any 2 BA spanners a 1/8 Whitworth is very near on size, close enough if the nuts are not too tight.

I’ve also found in my stash a 1/4” drive socket that will fit the base nuts and if I trim the length a bit and use a wobble bar it will do the job of the special base nut spanner nicely.

I’ll also need some ¼” BSF taps and a die to clean the cylinder head studs and nuts, better get some 2 BA as well so a call to Tracy Tools is on the cards as well.