Last time I was out on the Velo I found that there was no charge registering. Once I got back home I found that the problem lay within the generator.

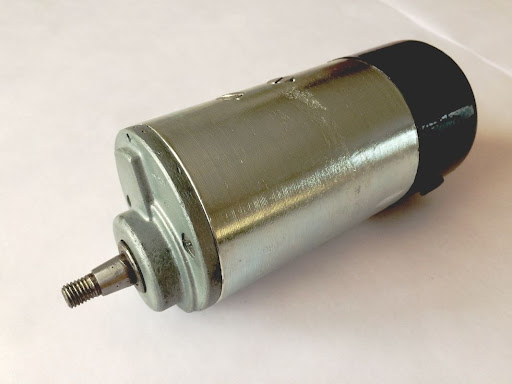

I still had the original generator on my Velo, a 6-volt Miller dynamo, which is very similar to the Lucas units more commonly fitted to most British bikes in the immediate post-war period.

These were a slightly upgraded version of the units fitted back in the late 1920’s which put out all of 36 watts at 6 volts!. The newer dynamos put out a nominal maximum of 60 watts reducing to about 45 watts at town riding speeds. This means that even with the newer unit the standard lights are low powered and give, at best, a 6-volt 36 watt headlamp!!.

They are normally a fairly reliable unit but mine is now over 50 years old and has given up on life so I decided to bite the bullet and rather than having it rebuilt I would upgrade and fit a more modern unit.

There is a French made replacement for these old style dynamos which is a direct replacement dimensionally for the old dynamos and so will fit in the existing dynamo cradle and use the existing drive and give double the output. While these units are not cheap, nor is the cost of a rebuild of a dynamo and when you take the benefit of decent lights and add that to the cost of a dynamo rebuild then things seem much more reasonable.

So I contacted my Velo parts supplier and ordered one of these “Alton” units, because it is an alternator rather than a dynamo it also requires a regulator/rectifier unit but this came as part of the package and is a standard “Podtronics” unit rather than a special so that fact may be useful later as I can also use it on the big Panther by changing the drive pulley.

Despite the postal hold ups it was delivered within two days, now I’ve just to get round to fitting it!!.

Owing to monsoon conditions this was put off for a while but did not prove difficult.

First thing was to disconnect the battery before starting to remove the old dynamo.

I removed the drive belt cover (for those not familiar with a Velo the dynamo is driven by a V-belt off the engine shaft shock absorber). Next was to slacken the nut on the end of the dynamo shaft before removing the drive belt.

Next off was the dynamo drive pulley, this has to come off because otherwise it blocks the removal of the belt drive inner cover which is next to come off, and then there’s only the dynamo clamping bolt to loosen off and the dynamo can be slid out of its cradle, not forgetting to undo the wiring cables from the dynamo.

The ‘Alton’ unit can now be slid into the cradle in place of the Miller and the belt inner cover fitted and the drive pulley fitted.

It is important to get the drive pulleys in line, otherwise you’re liable to have the belt jump the pulley or, at best, wear badly. Simple way to do this is to take a length of 6mm round bar and put a right-angle bend a couple of inches from one end.

If you now hook this into one of the pulleys then the free length gives straight line along the required drive line and so can be used to line up the two pulleys.

Once the pulleys are in line then all that’s left here is to fit the belt and set its tension by rotating the generator in its cradle.

Now we get complicated, it’s time to fit the reg/rec unit.

On the later Velos such as mine the regulator is fitted onto the rear mudguard, under the saddle and, nicely out of the way.

Looking for somewhere unobtrusive to mount it I settled – – – – on the rear mudguard under the saddle, where the original unit lived.

This has the advantage that I can utilise the existing cabling to connect the reg/rec into the bikes systems.

There are a pair of leads from the generator which match up to two of the leads from the reg/rec.

Of the other two leads from the reg/rec, one goes to the main ground point, which is under the tank anyway and the other is the power lead going up to the main switch.

Once everything was connected up and checked all to be working that was it and I now have the advantage of being able to run a decent headlamp rather than having to rely on just a time-served glow-worm in a jar.

Why did I go for the upgrade?. Well the Velo is still a practical road machine, it was about the top rated sports bike of its generation and is still well capable of coping in modern traffic. Its weak point was the low powered 6 volt lighting system.

With this new generator I now have a 12 volt system with good lights, in fact because the bike has a magneto and so no power demand to run an ignition system, I have power and to spare to run a spotlight as well if I so wish.

Before the conversion, if I was out with lights on I needed to really be above 40mph to keep the battery charged, riding at lower speed, as in towns, meant the loads did not balance and the battery would gradually drain down. Not only that but the lights were low powered, now I happily run a standard QH headlamp and can SEE where I am going after dark.