I’ve had a problem with the gears on the BMW combo for a while now, what’s happening is that it keeps jumping out of second gear under load and then dropping back in with a crunch.

I’ve been working round it by doing a double change up into third from first and not using second but that’s not fixing it and it’s a wide gap between first and third.

I recently had the chance to get another gearbox and jumped at it so now it’s time to change the gearboxes over.

As the sidecar limits access on one side, what is an easy job on a solo becomes a bit of a fiddle and the fact that it’s a /7 power train in a /2 frame does not help since it’s a tight fit!.

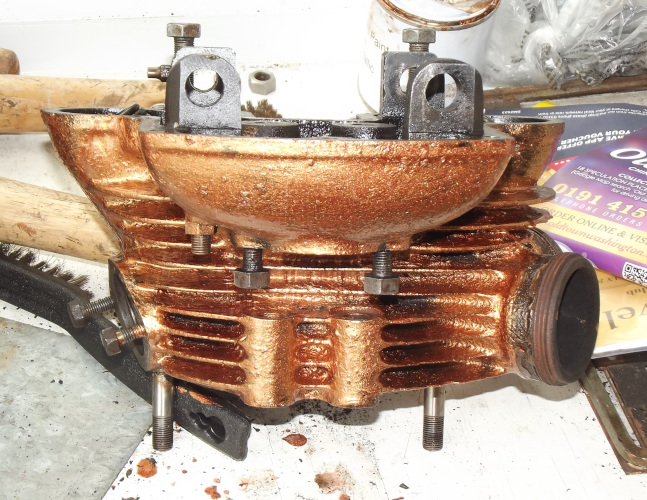

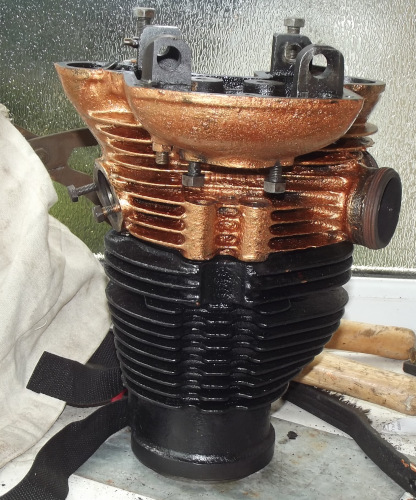

First thing is to run the rule over the replacement gearbox, all seems ok, changes gear without problems but the neutral switch is damaged, one of the electrical connections has been broken off, well I’ll just swap over the one from the current gearbox while I’m doing the swap.

So it’s out to the bike and get started, I need to clear the decks round the gearbox so we start by removing fuel tank and then the silencers.

Then it’s a case of take off both carburettors and their associated plumbing, I’ve left them attached to their cables and tucked them away at the front of the engine unit.

Now I need to remove both halves of the air-box. Left side comes away without problem, well it needs to, to be able to allow for the filter being changed but the right side hangs up, it’s not till I’ve removed the securing nut completely that I find a washer jammed in the slot that’s meant to allow the cover to slide off to the right side of the bike by just slackening the securing nut.

As the engine breather hoses go into the side castings of the airbox the easy way to get these covers off is to remove the top cover over the starter motor, because the ignition coils are positioned on the frame just above this cover it’s “a bit of a fiddle” to get it off and then we have the decks around the gearbox cleared for action.

But we’re not ready to remove the gearbox yet!, it’s still connected to the bike itself.

A BMW has a shaft drive and the shaft itself has a universal joint that bolts onto the output flange of the gearbox. This joint is under a rubber bellows and runs in oil so that needs draining and the bellows pushed back to allow access to the four 12-point head bolts securing it. Space is limited by the bellows so this is another right fiddle, and replacing them can be worse!.

As clearance with the rear sub-frame is tight it makes sense to remove the clutch operating arm, remembering to catch the return spring as it drops clear.

Now we can go round and slack off the four mounting bolts for the gearbox proper, as I have the combo’s battery mounted on the sidecar I have the main ground return from the battery secured to the lower right of these (remember this combo is a right-hooker!).

While it should now possible to remove the gearbox, clearances are VERY tight and to give more space the trick is to remove the rear swing fork pivot pins and move the complete rear wheel assembly back, it only needs to come back about an inch to make all the difference but of course up till now the bike has been standing on its wheels.

This means getting the jack out and lifting the rear end of the bike enough to drop the centre stand, because the bike has a 15inch rear wheel rather than the original 18inch, as well as a 16inch front wheel, to just try to simply lift her onto the centre stand as normal risks a rupture! But once you have her lifted up, dropping the stand becomes a safety measure, think of axle stands on a car.

Now to loose off the rear swing arm! First thing is to undo the rear brake linkage as this will prevent the wheel from being pulled back, undo the bottom ends of the rear suspension units, take out the bearing support pins and pull the wheel back.

Now comes the gear-change parts, this bike has the Kinematic assembly and the simple wire link has been updated with a rose-joint assembly.

There’s a lock-pin you need to remove from the front rose-joint that then allows the joint to split, once that’s done simplest way is to just drop off the entire left side footrest assembly.

Now the gearbox can have the mounting bolts removed, the top right one is a nut onto a stud into the main engine block and it is easiest to remove this completely, the gearbox can then be lifted clear, remembering to disconnect the neutral switch as you bring it away.

As mentioned before, I need to swap the neutral switches between the two gearboxes. I also need to fit the clutch pushrod into the replacement gearbox as this cannot be done with the gearbox in situ.

Next thing is to simply have a cuppa have a good think round and make sure nothing has been forgotten about before fitting the new gearbox in place.

While things are opened up it’s a good idea to clean and re-grease the spline drive on the clutch. This needs a black moly HP grease, but don’t overdo it! You don’t want any of that on your clutch friction plates!!

Now you offer up the box onto the bike, remember to fit the wires onto the neutral switch, it’s a real bitch of a job fitting them when the box has been installed, with the clutch push-rod pressed back into the gearbox align the input shaft with the centre bore of the clutch and slide the gearbox into place.

Once you have it home on the engine casing you can refit the mounting bolts and the stud. When you have that done it’s just a case of refit the rear swing fork into the frame and you can have the bike back on its wheels. Remember that you disconnected the rear brake!!

Then it’s just a case of reversing the disassembly work, fill the gearbox with oil, put about half of the spare gearbox oil into the swing arm and the jobs done.

Quick trial and find the neutral light not working, as this inhibits the starter it means the engine won’t start so it’s down and check the switch connections, I’d had a meter on the switch to ensure it worked before we started.

One of the switch terminals should go to a ground at one of the gearbox mounting bolts and this wire had broken at the tag of the terminal held under that bolt.

Sounds an easy fix, BUT, – the wire is now the exact length to reach the mount bolt tag, there is no extra length to allow it to have the end stripped back and fitted into a new tag and then to fit this under the bolt head!

Only access to this wire now is from underneath the bike so its a case of preparing an extender piece of wire and then to grovel alongside the bike, reaching under it, preparing the wire from the switch and then crimping on the extender, sounds easy but you try doing it!. Anyway, I managed it and made off the new connection under the bolt head.

Key back in, ignition ON and I’ve a working neutral light, try the starter and the engine turns over so next it’s a case of fuel on, hit the starter and she’s running again, time for a road test.