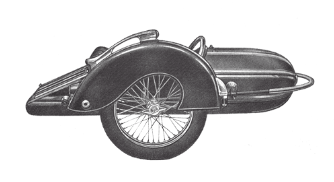

Now that I’ve taken the sidecar off the Panther I can again ride her as a solo.

First time out felt a bit strange, probably because it’s been on sidecar for a while and the tyres will have worn to suit a sidecar outfit.

Since it’s only been for around 1500 miles they’ll soon wear back to suit a solo so that’s no real problem, especially as she will not be used as a performance machine.

Once I got back home I realised that the headlamp was not working, in fact none of the electrics were!.

First thoughts were that I’d managed to blow the main fuse but a quick look showed that this was not so, and then I saw that the stop light was still working.

This showed that the battery was still charged and its connections were sound.

But the stop-light is not fed from the headlamp area, it has its own feed from the battery, so suspicion fell onto the wiring and it was out with the multimeter.

The wiring system on this old lady is laughably simple when compared with that on a modern machine.

There is a wire runs between the battery and the ammeter.

Another wire runs between the regulator and the main switch.

One runs from the switch back to feed the rear light and then I’ve added an extra one from the headlamp shell to the frame ground point and that’s the main fore and aft loom!.

There is in addition a connection between the ammeter and the main switch and then there’s the wiring going to the headlamp itself plus that to the speedometer bulbs and to the horn.

The headlamp is normally grounded through the frame of the bike but since I had added a grounding wire as a back-up, suspicion was on the battery lead to ammeter wire.

I used the multimeter to test between the ammeter and the headlamp shell and sure enough there was no power showing.

Suspect point was where the loom flexes as it exits from under the fuel tank and crosses to the headlamp shell.

Normally there would be only a small amount of movement here but I’ve had a sidecar fitted, this means that as with a sidecar fitted you actually steer by turning the bars there is much more movement, and hence flexing of the loom here.

Sure enough, I could feel a break in one of the wires here and so decided to splice in a new section of wire.

This meant taking the tank off to get access, so it had to be drained!, typically I’d just tanked up, luckily only to half-full!.

I opened up the loom at the break to find the wire had totally parted and so I pulled that wire out of the loom further back to under the tank to make a splice.

Until now I’d assumed it was the main battery feed wire forward had parted but it turned out to be the additional grounding wire I’d added! Shows how unreliable a frame ground can be!.

To be safe I checked by running a temporary ground wire from the headlamp to battery ground and – Lo and Behold everything worked!.

This made life much easier as the ground point inside the headlamp is much simpler to reach than the power point!.

Rather than just bridging the break I ran the new wire from the splice point under the tank direct to the headlamp ground, this meant I only had the one splice in the wire, less potential for problems!.

A swift check of the system again and everything was working so it was just putting things back together, add fuel and we were back on the road.