Well I’ve just been out in the garage to fit the new barrel onto the Panther only to find I’ve made a major cock up.

I had the barrel in place over the crankcases, slid the gudgeon pin into place, circlip fitted in place and slid the barrel down to seat on the cases and – – – IT DIDN’T BLOODY FIT!!.

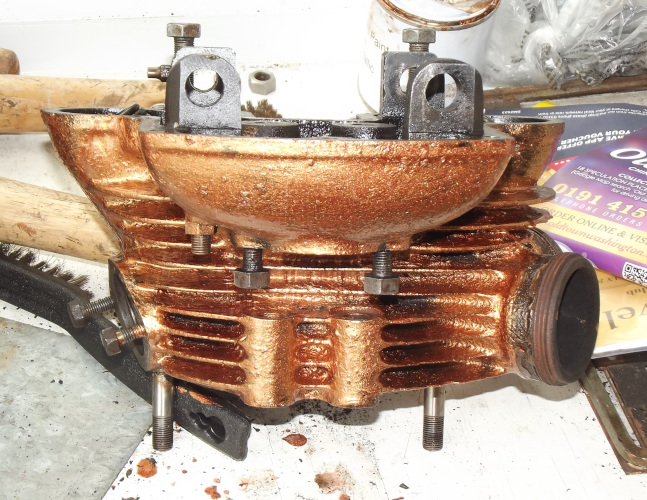

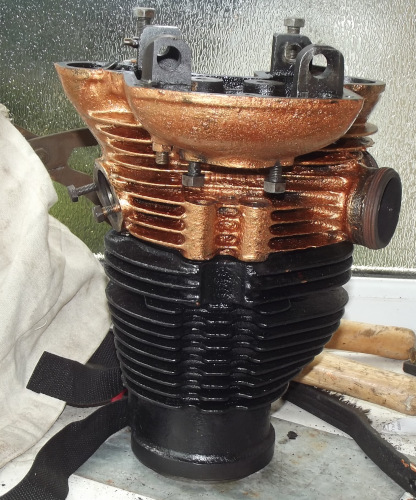

The barrel spigot was too large for the cases!

So out with the circlip and gudgeon pin, barrel off the bike again and start the inquest.

Vernier out and check the spigot outer diameter against that of the other barrel and it was definitely larger, What’s going on?.

Sudden thought “It can’t be!” but measure barrel lengths. The old barrel is 3mm shorter than the new!.

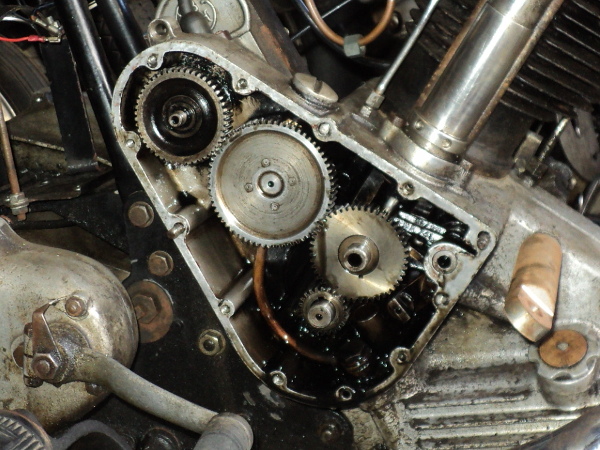

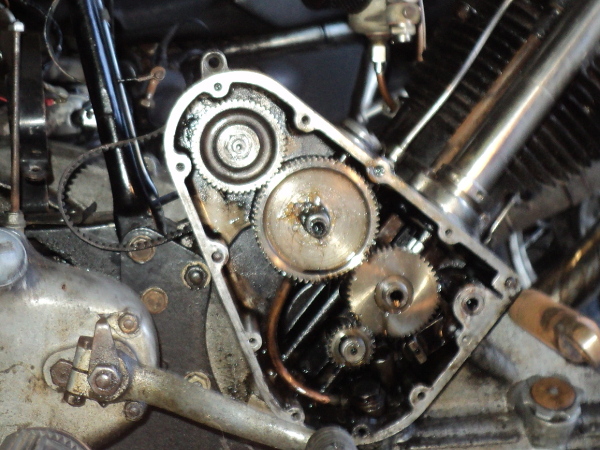

Yes, the barrel I had had bored, the one that had a slipper piston in it and was tagged as being for an M100 is in fact for an M120! Just what I need!.

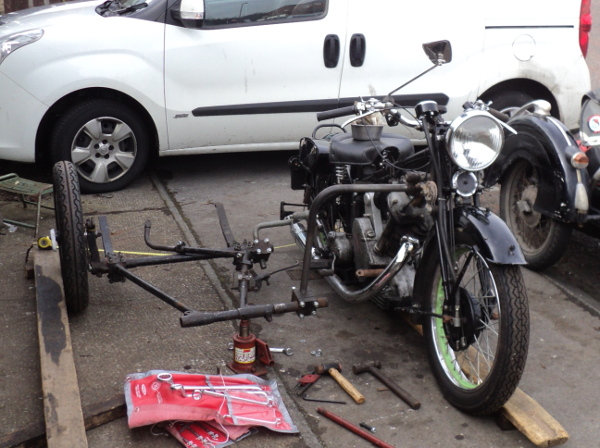

When I first built up the bike I’d got a job lot of spares as well, all said to be for the M100

There were 3 barrels, the one I’ve been running on, the one I now know to be from an M120 which has the new bore and piston and one other M100 barrel (Yes, I’ve measured it to be certain!). I know, I should have checked but the possibility never crossed my mind, especially as it had come with a slipper piston in it and the M120 did not use slipper pistons.

So a closer look at the two M100 barrels. There’s the one I’ve been running on and the “spare”. The spare turns out to have been bored out to plus 60thou while the other is on STD bore.

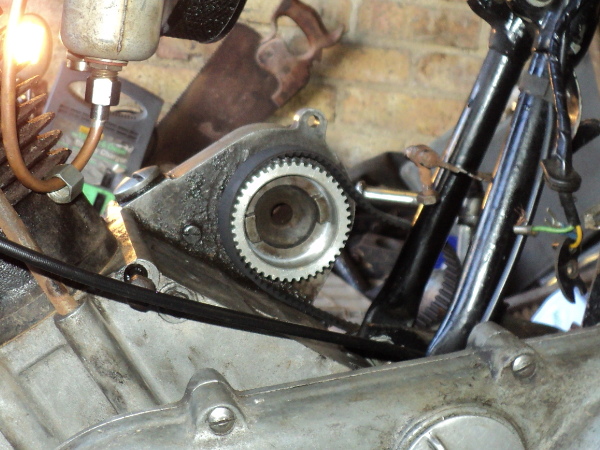

What is the wear like on them?. I used the old dodge of checking the ring gap in the unworn base of the bore and at half stroke and the “spare” comes out best with an increase of only 4thou.

The other barrel is about twice this, still plenty of life there but I decide I’ll put new rings in the “spare” and use that since I’m unwilling to bore either out for the Rover piston. Why had I not used this barrel originally? Quite simply because I had a set of new piston rings “in stock” to fit the barrel I did use.

So it’s now a case of clean up the outside of this barrel with the wire brushes and give it a coat of paint.

I got onto POC Spares for a set of new rings. I placed the order at about 10.00pm on the Wednesday night, parts arrived on Friday morning!! Well done to Old Foxy!!

Of course new rings meant that I had to set the ring gaps. I used the old advice of “4 thou for every inch of bore” and had to open up all three from a tight 10thou.

I cleaned out the ring grooves in the piston using the old rings to scrape out the crud, the middle ring had been a bit tight in its groove but all 3 are now an easy fit in their groove.

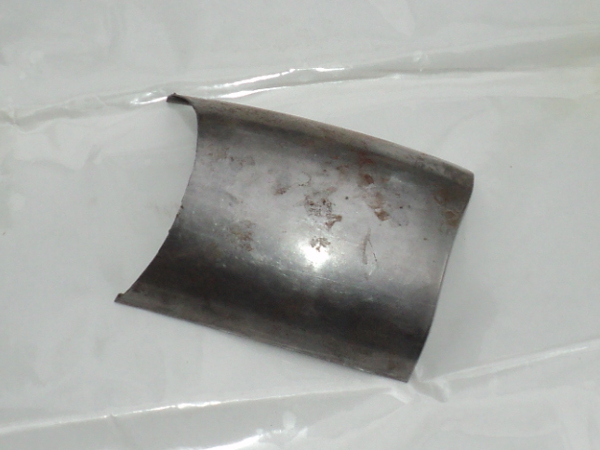

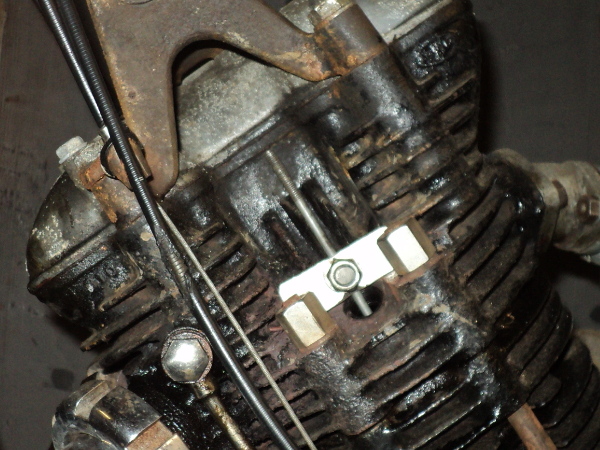

Because it was an old piston and I was not happy with the condition of one of the gudgeon circlip grooves I decided to fall back onto older technology and use gudgeon buttons rather than circlips, there’s a choice of materials here. My old Triumph uses these as standard and they’re phosphor-bronze, I know some of the racing boys are using Teflon or there’s also the option of aluminium.

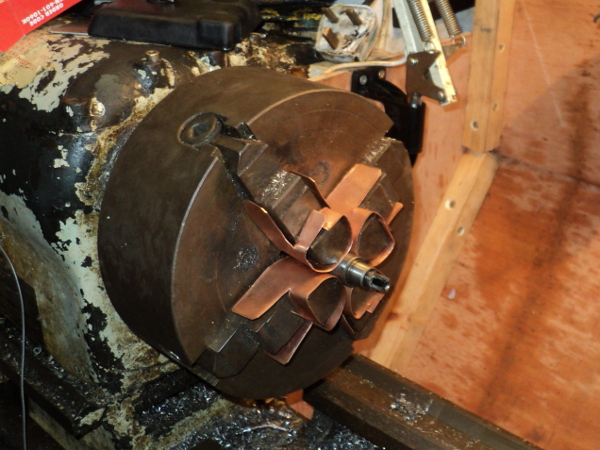

If I choose phossy-bronze, well it’s not an easy material to work with since it work hardens on sight, I’ve looked into Teflon but this means buying an industrial length bar of the stuff and it’s not a cheap material so it looks like I’m going for the aluminium option, I’ve a foot length “off cut” of inch bar in stock so it’ll give me an excuse to play on the lathe.

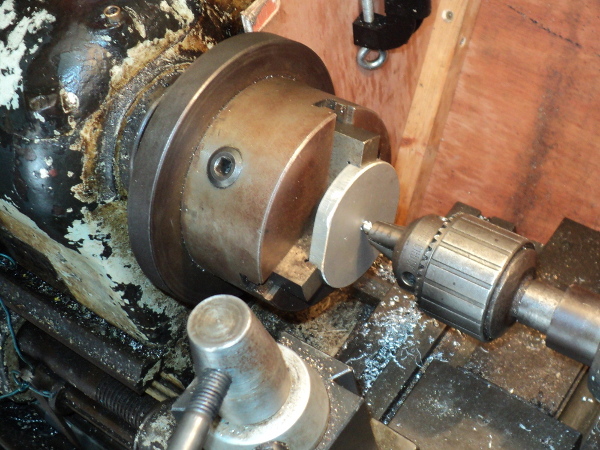

So first thing is to work out just what’s needed, sit down with the piston, the gudgeon pin, a vernier, a sheet of paper and a pen to work out dimensions and sketch out what’s needed, then it’s out to the lathe.

First was measure the length of the gudgeon pin, subtract that from the bore dimension and half the result. This gave me the length I needed for the gudgeon buttons, next was the diameter of the pin and then its bore, what was needed was a “top hat” to match these dimensions.

Pop the ally bar in the lathe and skim about an inch and a half length of the bar down to 7/8 inch diameter and check against the piston, I used the old piston from the M120 barrel as a gauge for this.

The bar was a tight fit in the piston so I skimmed another couple of thou off it and tried again, an easy slip fit!.

Next step was to skim the last 10mm of the bar down to be a snug fit in the bore of the gudgeon pin itself, as the pin is taper bored this proved a bit fiddly but it was managed.

Next was bore a 3mm hole down the middle of the bar, part off the first button to length and then repeat the whole process.

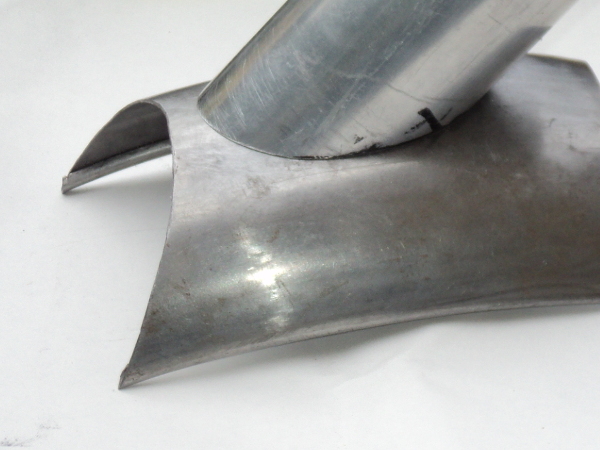

Snag here is that these buttons are flat faced, but they have to go against a round bore. A look on Google gave me the required clearance to skim a shallow taper onto the face so that only the central few mm of the button was able to touch the bore and as they have to run with a slight clearance to the bore, same as the piston skirt, it was a simple job to skim that in.

Now the acid test, put the buttons into the pin and try it in the bore, an easy fit with a nice clearance to each side, jobs a good ‘un!, now to build things up again.

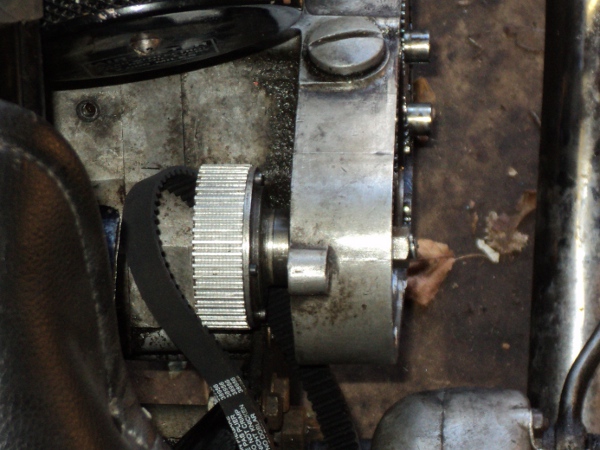

A not uncommon trick with a rebuild is to put the piston into the bore first and then lower it onto the head studs, sliding the gudgeon pin into place and fitting the circlips before sliding the barrel into place.

What isn’t said is that it can be a right fiddle getting the small end eye to line up with the gudgeon pin bores at all as the con-rod keeps trying to fall forward, and then you have to get the match exact enough that the pin will slide home through both the piston and the small end, remember that there is no clearance between these, it needs an exact match. At least there was no trouble with fitting the pin circlips since I was using the buttons.

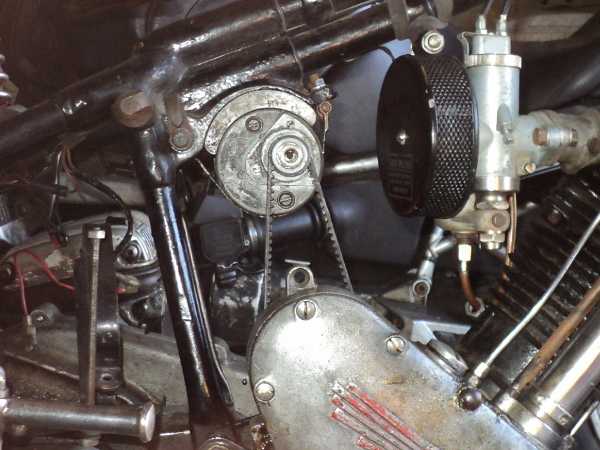

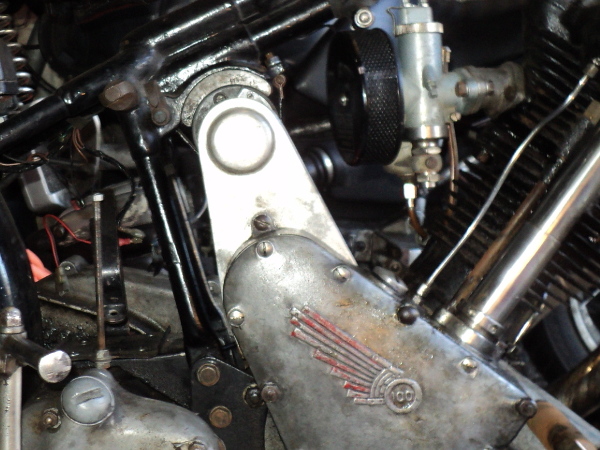

After that it was just put everything back in place, believe it or not the biggest fiddle was replacing the exhausts!.

What is needed here is for the flange on the pipe to fit flush against the stub on the head. If you try to put the complete pipe and silencer in place as a unit, the flange will be on a tilt against the stub and you will not be able to pull them flush to using the retaining nut to get a seal, you need to have just the pipe in place and pull up the nut while wangling the pipe around to make sure everything mates up square before rotating it into place and fitting the silencer last, – – – and then you have to repeat on the other side!.

All that’s left to do is fit the carb, then the tank, add some fuel and give her a kick.

Story book ending is to fire up first kick and settle to a steady tick over.

Well second kick the old bitch kicked back and it took another couple of kicks before she was running and the carb needed setting up.

On initial kick over compression was down but after taking a couple of miles run it came up to reasonable and it’ll take a couple of hundred miles to bed the new ring in so all in all I’m happy with the result, just have to see how much oil she’ll be using.

What to do with the rebored M120 barrel? Well I’m considering skimming the spigot down to suit and shortening the barrel, this would have to be done on a mandrel but it is possible, or I could always source another M100 barrel and bore that to suit the Rover piston, it’ll depend on oil consumption once the rings have bedded in.